Existing Compressed-Air Systems

There are more than 630,000 compressed-air systems in the United States running an average of

5,476 hr and consuming more than 91 billion KWH

of electricity per year. With a total installed horsepower

of 32.5 million, this equipment consumes

$4.2 billion of electricity per year.

Compressed-air electricity consumption

represents 2.66 percent

of the electricity consumed

by all sectors in the United States.

Table 1 is a summary of industrial-sector electricity

consumption.1 The industrial sector, which

comprises manufacturing and non-manufacturing

industries, accounts for 31.7 percent of the electricity

consumption in the United States. As can be

seen in the table, the manufacturing industry

consumes the bulk (85 percent) of the more than

1 trillion KWH of electricity used by the industrial

sector. The table includes a summary of the potential

energy savings of motor-driven systems in

the manufacturing industry, assuming a simple

payback of less than three years. The savings

for compressed-air systems alone is more than

$714 million a year, a reduction of 17 percent.

This equates to an annual average savings of $1,133

for each compressed-air system.

It is important to note that compressed-air

systems account for 15.8 percent of manufacturing-

industry electricity consumption. Compressed

air is used to spin tools, drive cylinders and linear

activators, atomize paint and other liquids, clamp

work in place, clean hard-to-reach areas, drive

piston air motors, blow soot, and fluidize fine

particles. In addition, it is used in material handling

and separation, grinding and drilling,

pneumatic control, and sandblasting,

among other applications.

The Compressor

To achieve an energy-efficient compressed

air design and desired air quality,

many factors must be considered. The

first and perhaps most misunderstood is

the compressor. Compressors are devices

that raise fluid pressure by more than

5 psig or increase the density from inlet

to discharge by more than 7 percent.

There are two basic types: positive displacement

(reciprocating or rotary) and

dynamic (centrifugal or axial). Both are

volumetric-flow devices.

Positive-displacement compressors entrap

a volume of air and reduce it. Characteristics

are constant flow and variable

pressure ratio for a given speed. Dynamic

compressors, on the other hand, depend

on motion to transfer energy. Flow is

continuous. The volumetric flow varies

inversely with this differential pressure

across the compressor.

When used in a tool, compressed air

supplies force. Force is equal to mass

times acceleration; therefore, the work

performed by a tool is dependent on the

mass flow of air through the tool. The

underlying factor in specifying compressor capacity, then, is the mass flow of air

delivered by the compressor. The following

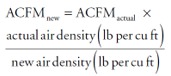

equation relates volume flow to mass

flow:

capacity, then, is the mass flow of air

delivered by the compressor. The following

equation relates volume flow to mass

flow:

m (lb wet air per min) =

ACFM (cu ft wet air per min) x

density (lb wet air per cu ft wet air)

The problem is that compressors are volumetric devices; therefore, their output

is influenced by changes in inletair

density. Air-density (pounds per cubic

foot) variation is caused by changes

in barometric pressure (and/or gauge

pressure), air dry-bulb temperature,

and water-vapor content (relative humidity).

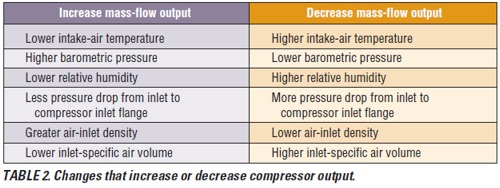

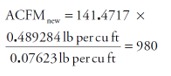

Table 2 lists some of the changes

that increase or decrease compressor

output.

volumetric devices; therefore, their output

is influenced by changes in inletair

density. Air-density (pounds per cubic

foot) variation is caused by changes

in barometric pressure (and/or gauge

pressure), air dry-bulb temperature,

and water-vapor content (relative humidity).

Table 2 lists some of the changes

that increase or decrease compressor

output.

Compressors installed at higher

elevations above sea level (or lower air

densities) get less air in each cubic foot

of intake air than they would if they

were installed at sea level. Table 3

presents performance data on ambient

airflow into and out of a rotary screw

compressor installed at sea level and at

10,000 ft above sea level. Note that the

ACFM-at-the-inlet and FAD flows

are only 1.38-percent lower at 10,000 ft,

even at a much lower inlet-air density.

This illustrates the compressor's ability

to hold its intake-volume flow rate.

There is, however, a significant change

in the mass-flow rate at 10,000 ft: The

mass flow into and out of the compressor

is 1,798.83 lb of dry air per hour, which

is 65.5 percent of the flow at sea level

(2,747.60 lb of dry air per hour). Like-

wise, the CAGI-SCFM at 10,000 ft is

65.5 percent of the CAGI-SCFM at sea level because it is a type of mass-flow

term. Note that compressor-discharge

ACFM also is significantly lower at

10,000 ft. All of this illustrates that mass

flow is related to air density, as well as

volume flow, and that the mass flow into

a compressor is equal to the mass flow

leaving the compressor, provided there

is no leakage.

level because it is a type of mass-flow

term. Note that compressor-discharge

ACFM also is significantly lower at

10,000 ft. All of this illustrates that mass

flow is related to air density, as well as

volume flow, and that the mass flow into

a compressor is equal to the mass flow

leaving the compressor, provided there

is no leakage.

Another loss attributed to humidity is

that of water-vapor mass flow, 85 percent

or more of which is removed by intercoolers,

aftercoolers, and dryer systems

as it enters a compressed-air system. The

compressor, then, should provide the

amount of mass flow required for the

worst-case scenario, which is a hot, humid

summer day with a low barometric

(and/or gauge) pressure. In most cases,

the predominant factor influencing compressor

output is inlet-air temperature.

When there is a significant drop in

inlet-air density (such as with the compressor

installed at 10,000 ft in Table 3),

the ACFM at the compressor intake

usually does not change much. According

to the above equations, to compensate for

the reduced air density and unchanged inlet

ACFM, the inlet mass flow must drop.

Because discharge mass flow is equal to

inlet mass flow (when there is no leakage),

this means that the discharge mass flow

must drop as well. This helps to explain

why the compressor at 10,000 ft in Table

3 had a significant drop in mass flow

(inlet and discharge) and CAGI-SCFM.

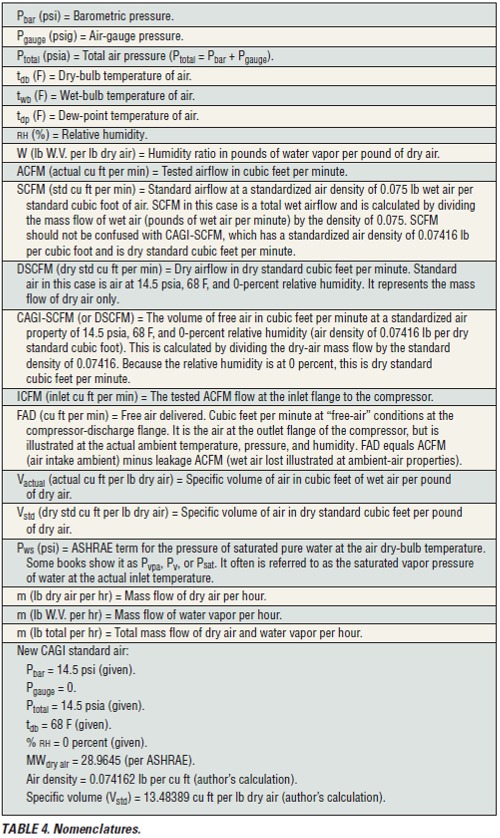

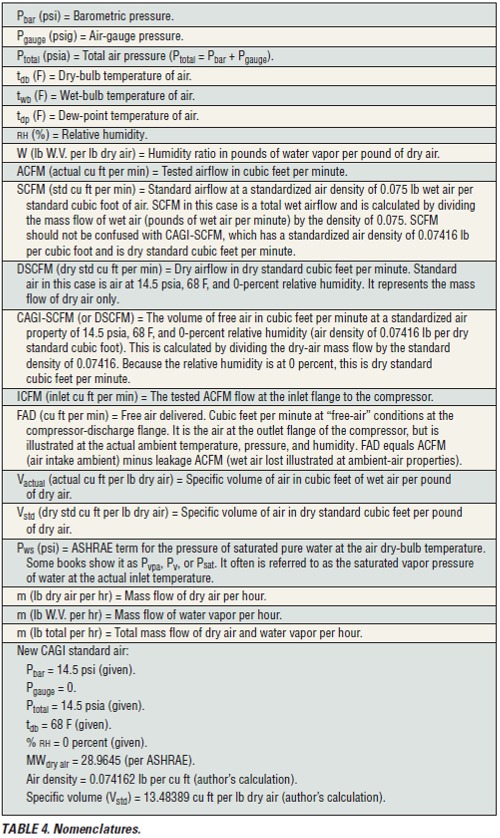

Performance Technologies

To better understand compressorsystem

sizing, engineers need to know

how compressor manufacturers specify

capacity with ACFM, ICFM, FAD, and

SCFM performance figures. These performance

terminologies have frustrated

engineers for many years. This section

will provide definitions, examples, and

equations intended to eliminate any

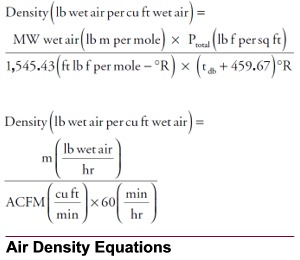

confusion. A list of nomenclatures that

will be used in this discussion is provided

in Table 4.

Figure 1 is a piping diagram of a compressor

system and aftercooler. Below the

diagram are the actual psychrometric

air properties and airflows. Above the

diagram are the actual conditions converted

to the psychrometric properties at

the air-intake air properties.

A lot can be learned by following the

mass flows in Figure 1. Mass flows, unlike

ACFM flows, are not affected by changes

in pressure or temperature (or water

vapor, in the case of dry-air mass flow).

The mass flow of dry air will remain

unchanged from inlet to discharge unless

there is leakage or loss attributed to

the use of pneumatic controls. CAGISCFM—

what the author prefers to call

DSCFM—is a type of dry-air mass flow

converted to dry standard cubic feet per

minute. DSCFM represents only the dryair

mass flow at the compressor-discharge

flange, the discharge mass flow after leakage.

In Figure 1, however, DSCFM flows

are provided at all points to reinforce

that they, like dry-air mass flows, do

not change unless there is leakage or loss

attributed to pneumatic controls.

It is important to note that the definition

of CAGI standard air has changed.

The new standard-air properties are

listed in Table 4. Figure 1 provides a few

equations that can be used to calculate

CAGI-SCFM flow.

Compressed-air-industry ICFM was

developed to avoid the confusion caused

by variable standards. This flow expresses

compressor inlet volume in terms of

actual inlet pressure, temperature, and

humidity. The problem is that ICFM can

be calculated at barometric pressure or

air-inlet-flange pressure, which is approximately

0.30-psi lower than barometric

pressure. Figure 1 calculates ICFM at

the inlet-flange pressure, as well as at the

inlet-flange dry bulb and humidity,

which are the same as the ambient dry

bulb and humidity. The ICFM flow is

1,021 cu ft per minute. If we calculate

the ICFM at the ambient total pressure

of 14.7 psia (instead of 14.39 psia), the

flow will be the same as the ACFM at

ambient, or 1,000 cu ft per minute. The

ACFM value will change as air density

changes because of variations in pressure

and temperature. The mass flows of dry

air and/or water vapor will not change

unless there is leakage, use of pneumatic

controls, or condensation.

The compressor manufacturer must

state the following psychrometric properties

of the ICFM flow:

• Barometric pressure (psi).

• Gauge pressure (psig).

• Total pressure (psia).

• Dry-bulb temperature.

• Relative humidity or humidity ratio.

• Air density (pounds of wet air per

cubic foot of wet air).

• Air density (pounds of wet air per

cubic foot of wet air).

• Specific volume (cubic feet of wet air

per pound of dry air).

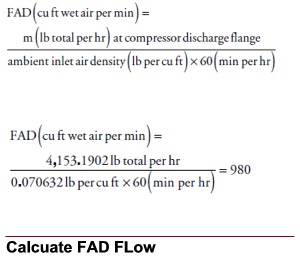

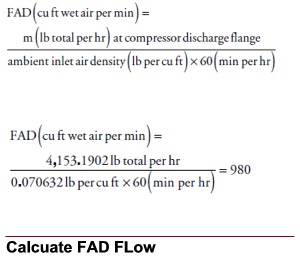

FAD also is a compressed-air-industry

term. It is the total moist airflow (dry air

and water vapor) discharged from the

compressor. Although FAD airflow is

expressed in cubic feet of wet air per

minute, it is not the actual ACFM at the

compressor discharge flange. In Figure 1,

the actual ACFM is 141 cu ft per minute.

The FAD airflow is a representation of

the actual mass flows of dry air and water

vapor, but expressed at the inlet-air

psychrometric air properties. In this case,

it is very important to understand the

psychrometric air properties chosen to

represent FAD airflow. In Figure 1, it is

the inlet-air conditions shown at the start

of the diagram (14.7 psia, 95 F, and 60-

percent relative humidity).

ACFM is the actual cubic feet per

minute of wet airflow (dry air and water

vapor) as determined by a Pitot-tube

traverse of the duct or pipe. In Figure 1,

the two-phase inlet airflow of 1,000

ACFM is made up of 966.77 cu ft per

minute of dry air and 33.23 cu ft per

minute of water-vapor flow. About 85

percent of the volumetric water-vapor

flow will be removed by the aftercooler

and refrigerated dryer, which will reduce

the amount of compressed air available

for use. To convert the ACFM flow to a

new set of psychrometric air properties,

use the following equation:

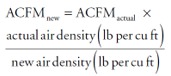

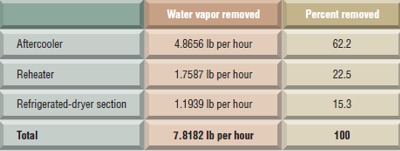

Using Figure 1, take the

ACFM at the compressor discharge

(141.4717 ACFM),

and convert it to ACFM at

the inlet-air properties:

Air leakage through shafts,

seals, and purge systems

usually is not discussed by

compressor manufacturers.

We also may have some

air usage for, say, pneumatic

controls. This would, of

course, reduce the compressor

FAD or the CAGISCFM

at the discharge of

the compressor. Figure 1 assumed

a loss of 2 percent.

The loss is 82.9849 lb of

dry air per hour and 1.7741

lb of water vapor per hour, or

20 ACFM at ambient air

properties.

[ back to top ]

Reference

1) Xenergy Inc. (1998).

United States industrial electric

motor systems market opportunities

assessment.

Compressed Air Systems Part 2:

Eliminating the Confusion

by William G. Acker

Eliminating the Confusion. Understanding the differences between ACFM,

ICFM, FAD, and CAGI-SCFM for improved

system design and equipment selection

Part 1 of this article reviewed the compressor-

performance variables ACFM (actual

cubic feet per minute), ICFM (inlet cubic

feet per minute), FAD (free-air delivery), and

CAGI-SCFM (Compressed Air &

Gas Institute standard cubic feet

per minute). Discussion was limited

to the compressor and aftercooler

portions of compressed-air systems.

This month, that discussion expands. Figures 2a

and 2b (pages 38 and 40) represent a complete

diagram of a compressed-air system and refrigerated

dryer, showing all energy, dry-air, and watervapor

flows; the lube-oil circuit; lube oil in the

compressed air and heat recovery; and heat into

the plant.

The rotary screw compressor in the diagram consumes 80 KW (273,020 Btuh) of electricity

at the compressor. The motor radiates 15,016 Btuh

of heat into the building, while the belt drive

radiates 7,740. The remaining 250,264 Btuh

is shaft power delivered to the compressor. The

compression of air picks up 70,163 Btuh, while

the lube oil picks up 180,101 Btuh. The air-cooled

aftercooler in Figure 2a is designed to remove heat

from the lube-oil and compressed-air circuits, as

well as motor heat and the heat of condensation. In

this illustration, the heat released into the building

is 256,475 Btuh, which could be used to preheat

boiler makeup water or outside makeup air. As a

rough rule of thumb, a 50-hp compressor at full

load rejects approximately 126,000 Btuh.

consumes 80 KW (273,020 Btuh) of electricity

at the compressor. The motor radiates 15,016 Btuh

of heat into the building, while the belt drive

radiates 7,740. The remaining 250,264 Btuh

is shaft power delivered to the compressor. The

compression of air picks up 70,163 Btuh, while

the lube oil picks up 180,101 Btuh. The air-cooled

aftercooler in Figure 2a is designed to remove heat

from the lube-oil and compressed-air circuits, as

well as motor heat and the heat of condensation. In

this illustration, the heat released into the building

is 256,475 Btuh, which could be used to preheat

boiler makeup water or outside makeup air. As a

rough rule of thumb, a 50-hp compressor at full

load rejects approximately 126,000 Btuh.

The aftercooler removes a significant amount of

the water vapor drawn in at the air intake. In

this case, the aftercooler removes 51.4 percent of

the water that enters the compressor system. This

is a significant amount that the refrigerated dryer

will not have to remove.

The refrigerated dryer has an

air-to-air heat exchanger, or what

some call a reheater. The reheater in

this case removes 10,909.60 Btuh

of heat from the compressed air before it enters the

refrigeration section of

the dryer. This significantly

lessens the burden

on the refrigeration section,

which removes

10,273.54 Btuh of heat

from the compressed air

itself. This heat is used to

elevate the dry-bulb

temperature of the leaving

air so that it is not

at 100-percent relative

humidity. The heat removed

by the reheater

also condenses 1.7587 lb

per hour of water vapor.

When the compressed air leaves the refrigerateddryer

section, the dry-bulb temperature is 37 F,

with a 37-F dew point (pressure dew point) and

0.000662 lb of water vapor per pound of dry air. To

get a feeling for the dryness of this air, air at sea-level

pressure would have to be at a dew-point temperature

of –7.2 F. To put it another way, if the air were

at 60 F, the relative humidity would be

at 6.1 percent, which, of course, is very

dry. The air-cooled-condenser section of

the dryer must remove heat from the

refrigerant, which is heat from cooling

the compressed air and heat from the

refrigerant compressor. The air entering

the air-cooled-condenser section then

picks up the refrigerant heat and fan

heat and discharges the total heat into

the building. The total heat removal

in this case is 19,497 Btuh, which is

dumped into the building. To make use

of this waste-heat energy, some plants use

water-cooled condenser sections, which

can be used to heat process water, or a

heat-recovery unit, which can be used to

supplement building heating.

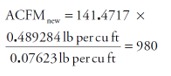

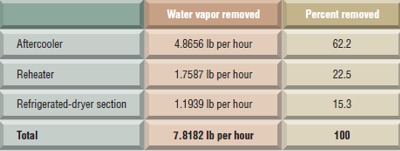

Water-vapor removal in figures 2a and

2b occurs at the aftercooler, the reheater,

and the refrigeration section of the dryer

system. The amount of water vapor removed

by each section is listed in Table 5.

Water vapor entered the compressor at

a rate of 9.465 lb per hour. After all

removal, the rate was 1.6468 lb per hour,

a reduction of 82.6 percent.

The figures also illustrate the amount

of oil released into the compressed air.

This oil exists as vaporized oil and aerosol

(colloidal particles) oil. The total amount

released into the compressed air after

the air/oil separator is 0.0150 lb per hour,

or 6.0 ppm (mass). The oil in this example

is a mineral oil. Excessive foaming

in the compressor lube-oil circuit will

cause an increase in lubricant carryover

in the compressed-air stream. The annual

oil loss, assuming 8,400-hr-per-year

operation, is 18.4 gal. The oil-holding

capacity of this compressor is 22 gal, so it

will be necessary for maintenance crews

to replace the lost oil throughout the

year. The oil remaining in the air after

the high-efficiency coalescing filter is

0.00003 lb per hour; therefore, 99.8 percent

(0.01497 lb per hour) was removed

by the entire system. The coalescing filters

remove the aerosol oil in the compressed

air. Vaporized oil can be removed

by dropping the temperature of the compressed

air, which condenses the oil, or

by using a vapor-removal filter. One type

of vapor-removal filter is the activatedcarbon

cartridge filter bound in a nonwoven

polyester substrate.

The compressed-air system removes a

total of 7.8182 lb of water per hour and

0.01497 lb of oil per hour. In some cases,

the water and oil are collected in a central

collection-tank system and sent to

an oil/water separator. The oil in this

condensate is 1,991 ppm (mass), which

is too high a concentration for some

wastewater regulatory agencies. The

required maximum concentration discharged

to a wastewater-treatment plant

usually is 5 to 100 ppm (mass). Condensate-

separation systems are designed to

remove oil from water to meet wastewater-

code requirements.

Designing an energy-efficient compressed-

air system with adequate compressor

capacity is not easy. It requires the

elimination of excessive pressure losses

on inlet and discharge piping, filter systems,

coolers, and dryer systems. It also

requires the removal of contaminants,

such as water, oil, pipe scale and rust, and

air-intake particulate. To select a compressor,

an engineer first must identify

the SCFM usages and convert that

required flow to a mass-flow number.

This eliminates confusion over toolusage

SCFM and CAGI-SCFM. The

engineer then must identify the worstcase

air-intake psychrometric properties

to ensure adequate capacity on the worstcase

day. Having identified the required

compressor output, the engineer can

review bids, comparing units based on

efficiency, internal losses, power requirements,

total installed cost, and lifetime maintenance costs.

maintenance costs.

To ensure energy efficiency, pressure

drops must be kept low. Excessive pressure

losses from undersized or dirty

piping, filter systems, aftercoolers, and

dryers entail more brake horsepower

at the compressor and higher annual

electricity consumption. An excessive

pressure drop of 1 psi for a 1,000-CAGISCFM

compressor system will cost

more than $630 in added electricity

consumption a year. Therefore:

• Piping should be designed for 0.2 to

0.3 psi per 100 ft of pipe (or about 50 ft

per second).

• Filter systems should be carefully

selected, and all systems should be properly

maintained to reduce the demand

for electricity.

• Regulators should be properly

selected for systems that do not require

full pressure.

• Inappropriate uses of compressed air should be eliminated.

• Water-cooled compressors, watercooled

intercoolers and aftercoolers, and

oil coolers should be carefully selected.

• High pressure for compressed-air

tools, such as paint guns, grinders, and

sandblasters, should be avoided because

increased pressure above design pressure

only causes these tools to use more air.

Compressed-air control systems help

control pressure to plus or minus 2 psi.

• If the compressor building is of the

high-temperature, high-humidity variety,

the intake air should come from an

outside-air intake, which will reduce the

compressor brake horsepower and dryer

load, as well as the electricity consumption

of the compressor and dryer system.

Conclusion

The design steps taken during system

planning have direct effects on a system's

overall operation and maintenance;

therefore, it is important that an experienced

engineer and an experienced

compressor manufacturer be involved.

This will eliminate excessive operating

costs and operational problems.

[ back to top ]

Acknowledgements

The author wishes to thank the

following companies for their assistance

in the preparation of this article: Kaeser

Compressors Inc., Van Air Systems Inc.,

Airtek, Pneumatech Inc., and The Hankinson

Corp.

Bibliography

• Air Power USA. (2002). Energy savings in compressed air (11th ed.). Pickerington, OH: Air Power USA.

• Atlas Copco. (1999). Compressor installation manual. Atlas Copco.

• Van Ormer, H. (1989, January). Get better service from your packaged rotary compressor. Power, pp. 30, 31.

|

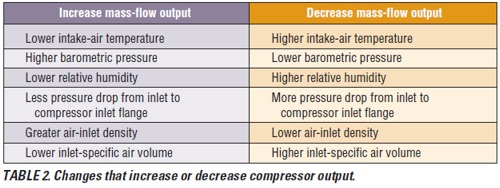

• Air density (pounds of wet air per

cubic foot of wet air).

• Air density (pounds of wet air per

cubic foot of wet air).

capacity, then, is the mass flow of air

delivered by the compressor. The following

equation relates volume flow to mass

flow:

capacity, then, is the mass flow of air

delivered by the compressor. The following

equation relates volume flow to mass

flow: volumetric devices; therefore, their output

is influenced by changes in inletair

density. Air-density (pounds per cubic

foot) variation is caused by changes

in barometric pressure (and/or gauge

pressure), air dry-bulb temperature,

and water-vapor content (relative humidity).

Table 2 lists some of the changes

that increase or decrease compressor

output.

volumetric devices; therefore, their output

is influenced by changes in inletair

density. Air-density (pounds per cubic

foot) variation is caused by changes

in barometric pressure (and/or gauge

pressure), air dry-bulb temperature,

and water-vapor content (relative humidity).

Table 2 lists some of the changes

that increase or decrease compressor

output. level because it is a type of mass-flow

term. Note that compressor-discharge

ACFM also is significantly lower at

10,000 ft. All of this illustrates that mass

flow is related to air density, as well as

volume flow, and that the mass flow into

a compressor is equal to the mass flow

leaving the compressor, provided there

is no leakage.

level because it is a type of mass-flow

term. Note that compressor-discharge

ACFM also is significantly lower at

10,000 ft. All of this illustrates that mass

flow is related to air density, as well as

volume flow, and that the mass flow into

a compressor is equal to the mass flow

leaving the compressor, provided there

is no leakage.

consumes 80 KW (273,020 Btuh) of electricity

at the compressor. The motor radiates 15,016 Btuh

of heat into the building, while the belt drive

radiates 7,740. The remaining 250,264 Btuh

is shaft power delivered to the compressor. The

compression of air picks up 70,163 Btuh, while

the lube oil picks up 180,101 Btuh. The air-cooled

aftercooler in Figure 2a is designed to remove heat

from the lube-oil and compressed-air circuits, as

well as motor heat and the heat of condensation. In

this illustration, the heat released into the building

is 256,475 Btuh, which could be used to preheat

boiler makeup water or outside makeup air. As a

rough rule of thumb, a 50-hp compressor at full

load rejects approximately 126,000 Btuh.

consumes 80 KW (273,020 Btuh) of electricity

at the compressor. The motor radiates 15,016 Btuh

of heat into the building, while the belt drive

radiates 7,740. The remaining 250,264 Btuh

is shaft power delivered to the compressor. The

compression of air picks up 70,163 Btuh, while

the lube oil picks up 180,101 Btuh. The air-cooled

aftercooler in Figure 2a is designed to remove heat

from the lube-oil and compressed-air circuits, as

well as motor heat and the heat of condensation. In

this illustration, the heat released into the building

is 256,475 Btuh, which could be used to preheat

boiler makeup water or outside makeup air. As a

rough rule of thumb, a 50-hp compressor at full

load rejects approximately 126,000 Btuh.

maintenance costs.

maintenance costs.